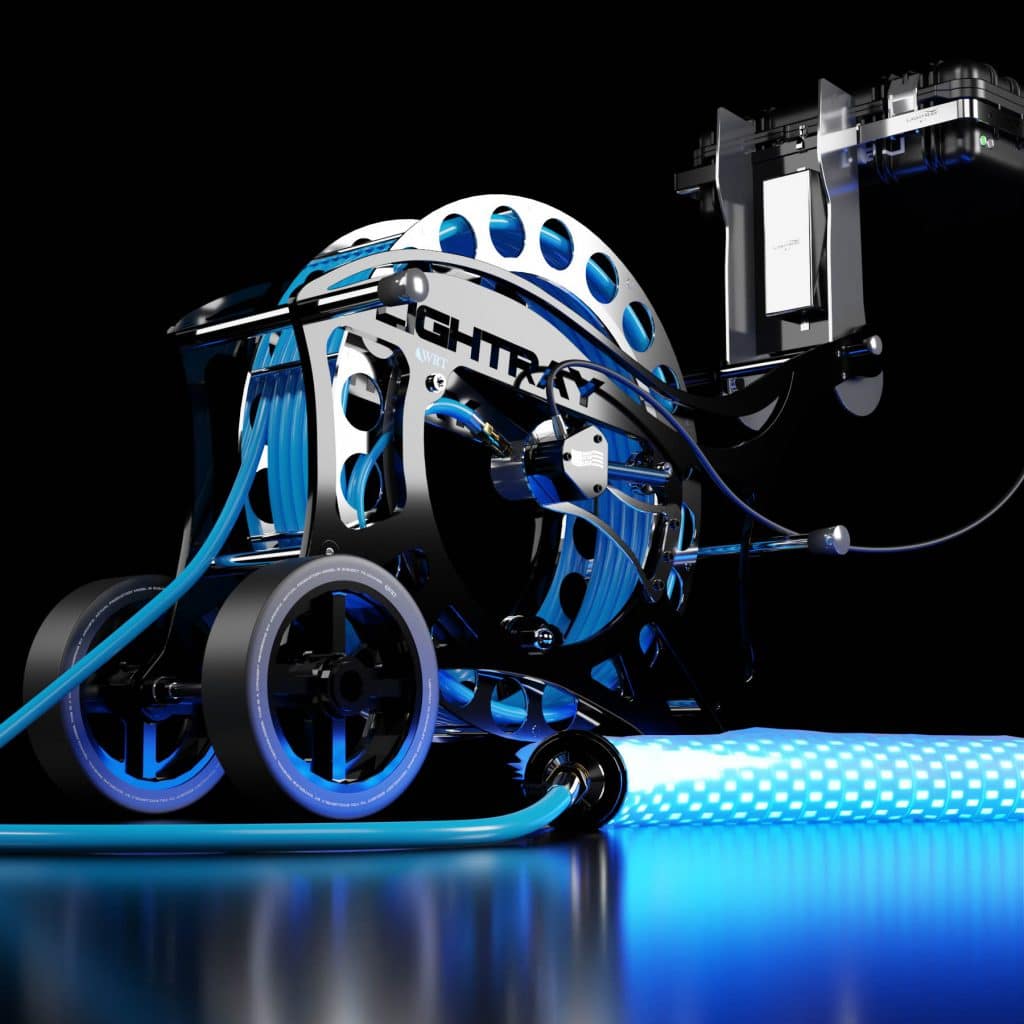

LIGHTRAY LR3

UV Spot Repairs

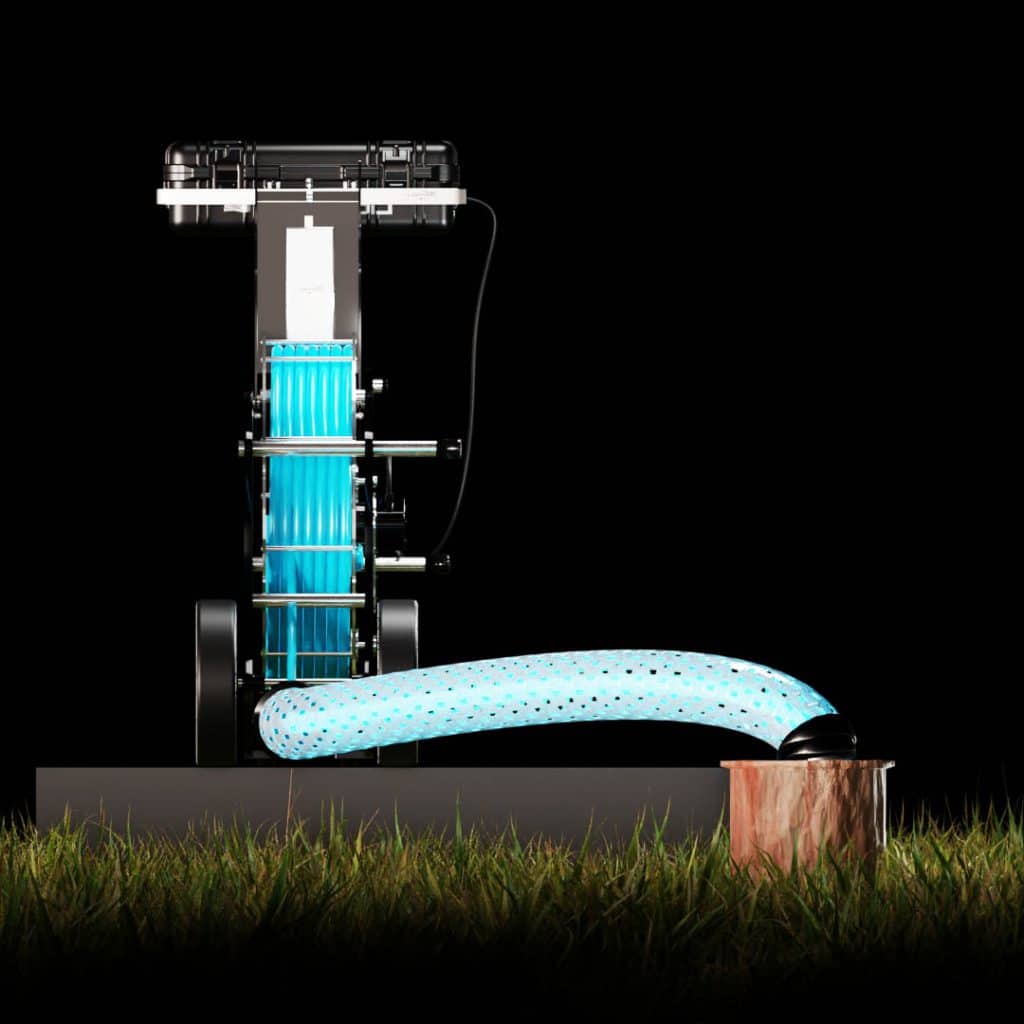

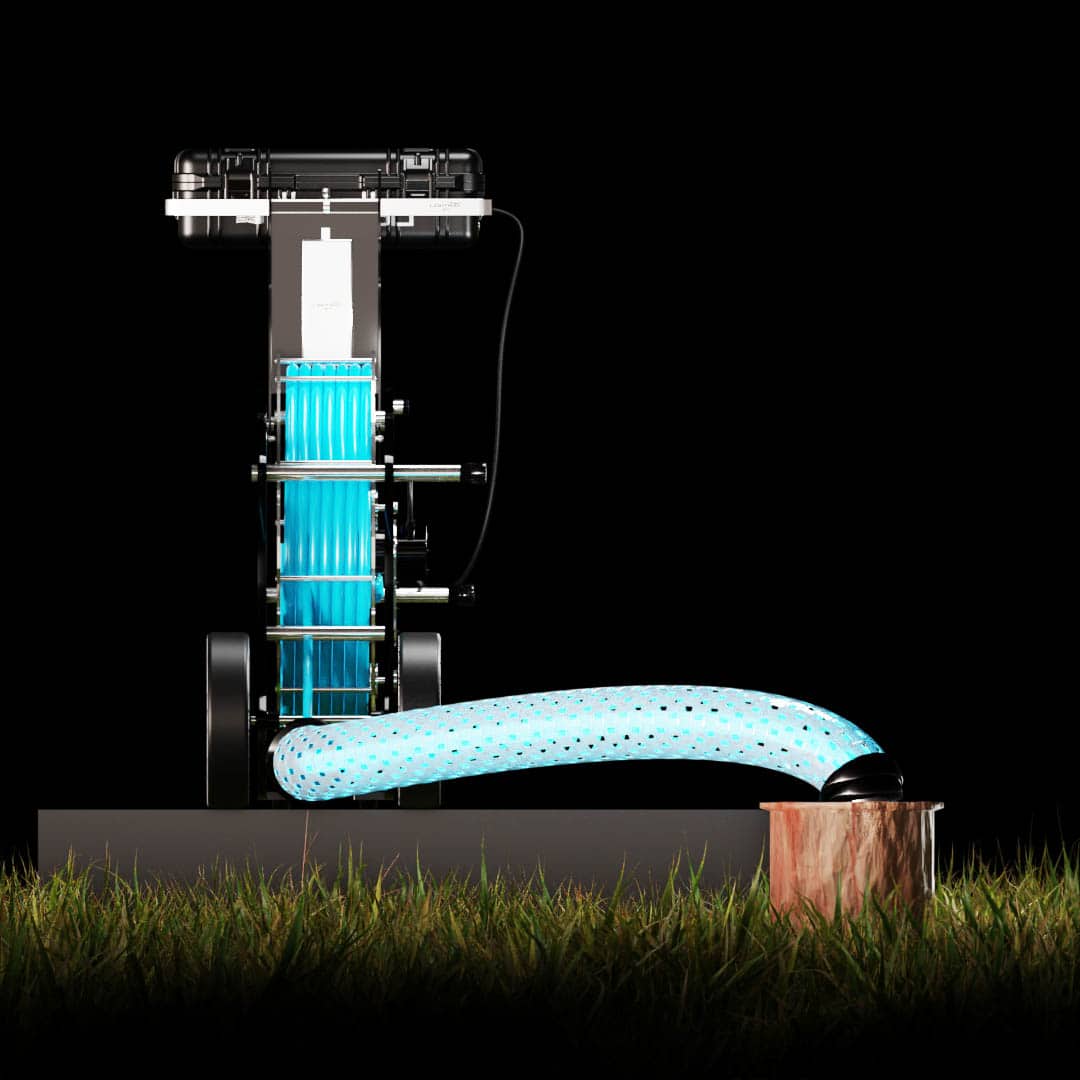

The new LightRay LR3 LED UV system is the most advanced UV cast in place pipe technology allowing the operator complete control of the casting process. Our patent-pending, state-of-the-art technology can significantly reduce your costs and risks when compared to traditional thermo-setting or ambient-cured CIPP liners, creating new opportunities for plumbers and municipal contractors.

lightray = Better than all the rest

LightRay’s state-of-the-art Cast-in-Place-Pipe technology ushers the Trenchless industry into the twenty-first century, offering new opportunities for plumbers and municipal contractors by significantly reducing time and resources, lowering risks and costs with much faster and higher quality results compared to the older traditional thermal heat or ambient curing processes.

lightray spot repair

Perfect Cast in minutes

The LR3 is both a pull-in-place and spot repair system giving you the flexibility to perform both operations by only changing the proprietary double strand cold LED repair packer. The LightRay non-VOC resin is pre-impregnated into the high-performance fiberglass liner and shipped ready to install for ZERODIGTM small diameter pipe infrastructure repairs. Once the install site is prepped, casting times in under 10 minutes can be achieved eliminating the risk of premature or prolonged curing times due to temperature variations.

Repairs pipe diameters of 3-, 4- or 6-inches including transitions

features of lr3

- Repairs pipe diameters of 3-, 4- or 6-inches including transitions

- The 100-foot hose couples with 5-, 10- or 20-foot packers to perform repairs

- Casting times of 10 minutes or less

- Liner materials arrive ready to install with no wet-out needed

- Easily navigates 45 and 90⁰ bends

- Training included and 24/7 support

- Designed, built, and supported in the USA

a true cold LED double strand system

packer + liner + resin

The patent pending LightRay packers are a proprietary cold LED double strand system offered in standard lengths of 5, 10 and 20 feet. Offered in diameters of 3, 4 and 6 inches, these UV packers require only 24-volts to cure and are protected and reinforced by a specialized silicone bladder for multiple uses and sustained durability.

The leading-edge navigation spring assists in going around bends and can house a radiofrequency device for location and tracking below ground or within walls and floors. In addition, the spring is removable allowing the hook to be exposed for all pull-in-place applications.

- Available in 3-, 4- and 6-inch diameters

- Double strand, cold LED lights for industry leading cure times

- Reinforced, multiple sized silicone bladders

- Leading edge removable spring guide exposes pull hook

- Specialized retrieval harness

- Quick disconnect system for easy packer switching

be up and running in minutes

ready to install

No more carrying resin materials in your truck or trailer and no need to measure and mix on site. LightRay liners arrive ready to install without any need for refrigeration. This greatly reduces the variability from mixing and preparing liners but also eliminates the requirement for extra equipment in the field allowing for rapid deployment of the system.

The LightRay LR3 system incorporates non-thermal UV casting resins along with high-strength flexible fiberglass pipe liners. No matter what the current temperature is above or below ground, the casting times are consistent anytime and every time, all in under 10 minutes.

- Resin impregnated liners in 3-, 4- and 6-inch diameters including transitional flex

- Casts in as little as 5-10 minutes

- No refrigeration necessary and a 6-month shelf life when stored in a controlled environment between 50-70 degrees

- Standard UV resins are non-VOC (no odor)

- Exceeds the structural requirements of ASTM F1216

- Sold in rolls of 50, 100 and 300 feet

did you know...

lightray is proudly made in the u.s.a.

The LightRay product line is completely designed, manufactured, built and supported in the United States of America! The quality is best in class and you can trust Waterline Renewal Technologies to be here for you if and when you need support on this system.

Made in the U.S.A. means a lot. We take great pride in manufacturing this ultraviolet lining system here in the United States. Our pride shows in the component quality & longevity of this new UV system.

dont wait... be one of the first in line

Now is your chance to take your sewer lateral lining game to the next level. Reserve your new LightRay LR3 system today and be the best sewer contractor you can be.

Offer your clients the very best in UV curing technologies.